|

|

|

|

| Home > Business > MWM |

|

| |

|

| |

|

|

|

|

|

|

| MWM gas engine technology |

MWM gas engine series |

MWM engine specials |

|

|

|

| - Air-gas-turbo-charging |

- Product range |

- MWM combustion measuring |

|

|

| - Combustion chamber temperature control |

- MWM TCG 2015 V8 |

- MWM chamber spark plug |

| - MWM TEM Evolution |

- MWM TCG 2016 V12 |

|

| |

- MWM TCG 2020 V20 |

|

| |

- MWM TCG 2032 V16 |

|

|

|

|

| |

|

| |

| |

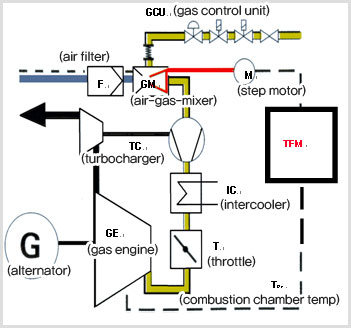

- Dense power concentration

- More accurate governing of the air-fuel-mixture at atmospheric pressure

- Homogenisation of the air-fuel-mixture by the compressor of the TC

- Enhanced efficiency

- No pre-pressurising of gas necessary

- No danger of backfiring due to low combustion speed by extremely lean mixture formation

- Flexible use for different types of gases |

|

|

- Optimum efficiency

- Homogenisation of the air-fuel- mixture by TC and intercooler

- No pre-pressurising of the gas required

- Reliable compliance to NOx, CO and HC emission limits |

|

- No pressure loss during mixture formation. Enhanced power output at max. efficiency.

- Also with changing mass flow of the gas, the air-gas ratio remains to be constant.

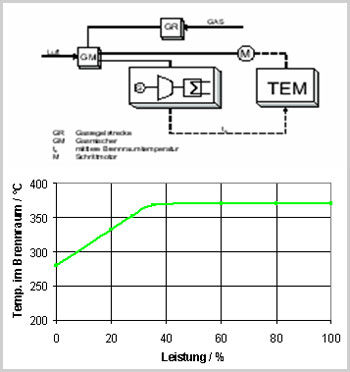

- Using the combustion temperature, e.g. the emission control of the engine is governed through TEM by adjusting the air-gas ratio. |

|

- Direct physical dependency of control variable and set value

- Only slight variations of TBr per working cycle

- Different loads or charging pressures have hardly any influence on TBr

- Influences out of gas type on TBr are of order two only, so negligible

- Same TBr mean same emission levels

|

- All control, measuring variables are collected and processed centrally

-

Also plant control circuits can be regarded, e.g. compressor control, heat demand, etc. |

- Remote operation and remote diagnosis allow plant operation via modem-

- including handling of warning and fault messages |

|

|

|

|

|

|

| |

2015 |

180 - 240 kW |

|

| |

2016 |

323 - 800 kW |

|

| |

2020 |

970 - 2.070 kW |

|

| |

2032 |

3.000 - 4.000 kW |

|

- Pm / Pel : 240 kWm / 230 kWel

- pme : 12,1 bar

- speed : 1.500 U/min

- e: 12 : 1

- bore/stroke : 132 / 145 mm

- displacement : 15,9 dmę°

|

|

- nat. gas: 649 kWBr

- lube oil 0,15 g/kWh

hel / hth: 35,4% / 54,1% |

- Pm / Pel : 600 kWm / 580 kWel

- Pme : 18,3 bar

- e : 12 : 1

- Bore/stroke : 132 / 160 mm

- Displacement : 26,3 dmę°

|

|

- nat. gas : 1.422 kWBr

- lube oil 0,15 g/kWh

- hel / hth : 40,8% / 39,2%

|

|

- Pm / Pel : 2.070 kWm / 2.014 kWel

- pme : 18,7 bar

- speed : 1.500 U/min

- e : 13,5 : 1

- bore/stroke : 170 / 195 mm

- displacement : 88,5 dmę°

|

- nat. gas : 4.706 kWBr

- lube oil 0,3 g/kWh

- hel / hth : 42,8% / 43,0%

|

|

- Pm / Pel : 4.000 kWm / 3.880 kWel

- pme : 17,7 bar

- speed : 1.000 U/min

- e : 12 : 1

- bore/stroke : 260 / 320 mm

- displacement : 271,8 dmę°

|

- nat. gas : 9.336 kWBr

- lube oil 0,4 g/kWh

- hel / hth: 41,9% / 44,0%

|

- Patented chamber spark plug : 1 - pre-chamber , 2 - plasma outlets

- extremely enhanced mixture ignition

- lower NOX emissions

- up to 10 times longer spark plug life |

- TCG 2020 and 2032 Series: Miller Cycle

- Miller: Inlet-valves

- Close before BDC

- The induced re-expansion of the mixture lowers the temperature and results in better efficiency |

- combustion behaviour of methane : retarded start of combustion

- Measuring set-up : photon radiation measurement with optic fibres

|

|

|

|

|

|

|